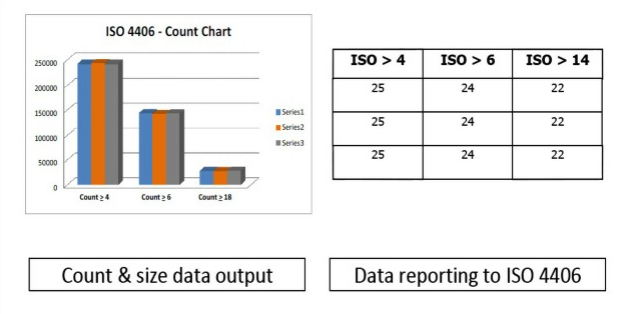

Lube Oil Particle & Water Analyzer

The presence of solid particles and water in lubricating and hydraulic oils can be problematic as they increase wear of moving parts, clog system filters and promote corrosion throughout the system. Detecting solids and water in theseoils is crucial in managing the operation of equipment and enhancing its effective life cycle. Knowledge of particle shape, in addition to count per mL, enables the user in many cases to assess the type of particulate present and its cause which can assist in pinpointing future points of system failure and preventing them.

Dynamic Imaging

High Speed, High Resolution and High Magnification images result in particle count and categorization capability in one measurement. LED advancements have improved particle detections due to brighter, more consistent lighting fields, as well as the ability to analyze high speed flows.

Shape parameters allow software to discern between solid particles, water droplets and air bubbles revealing a more complete condition of the analyzed fluid.

Shape parameters also enable engineers to assess the type of particles present according to their shape, and to perhaps determine a source of the fatigue or wear.

Video

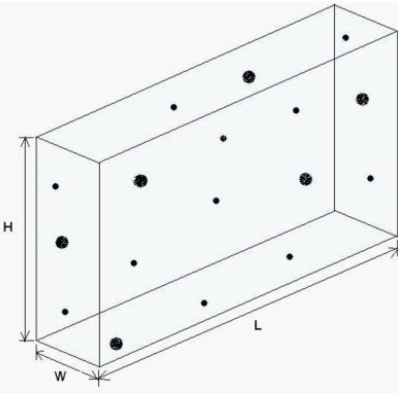

IMAGE BASED ANALYSIS AND HOW IT WORKS

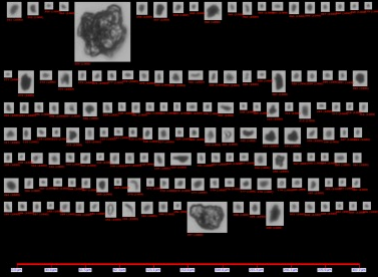

Based on their visual characteristics (shape, percent fill, translucence…) the software can differentiate between the different types of particulate within the lube oil.

Solid particles are irregularly shaped. Water droplets are visualized as circular particles while gas bubbles are also circular but typically have a higher percent fill. Visual verification ensures the desired particles are included in the specific data set.

Vision is now used to monitor and analyze a wide range of multiphase mixtures such as oil and solids in produced water, solids and water in fuels and lube oils, percent solids in separation and filter break applications

In the past all these parameters would be hand programmed into the software and now with Canty’s AI software they are programmed in ahead of time and visually verified

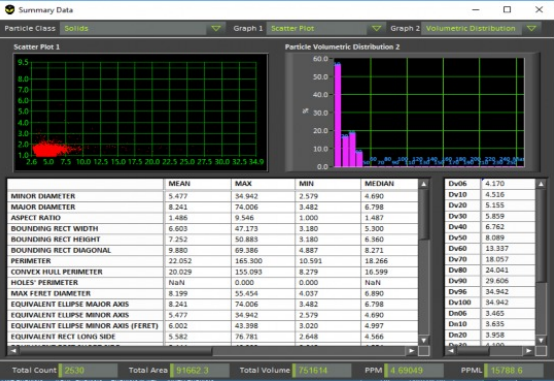

Shape Parameter | Value |

|---|---|

Circularity | 0.7 |

Aspect Ratio | 2.23 |

% Holes Area | 0% |

Shape Parameter | Value |

|---|---|

Circularity | 0.33 |

Aspect Ratio | 1 |

% Holes Area | 25.50% |

Shape Parameter | Value |

|---|---|

Circularity | 0.13 |

Aspect Ratio | 0.13 |

% Holes Area | 92.50% |